Factory direct attack: GMi Hong Kong-produced oil-electric hybrid tour bus grand structure! Is the all-electric bus the goal?

Although Hong Kong vigorously advocates innovative technology, do you know to what extent Hong Kong's innovative technology has gone? Recently, one of the most innovative and technological projects is12m plug-in diesel and electric hybrid coach developed by local manufacturer GMi

It was previously exhibited at the International Environmental Protection Expo at AsiaWorld-Expo. Although this oil-electric hybrid tour bus seems to be no different from ordinary tour buses, when ezone.hk As soon as the reporter went to the office of GMi in San Tin, Yuen Long, and the factory of the China-Hong Kong body manufacturing plant responsible for the production of the body, he directly hit the production of the oil-electric hybrid bus, and he can tell you with certainty.Speaking of it, there is a difference. As for what is special about this oil-electric hybrid coach, it is up to Lu Chi-pei, the managing director of GMi, and Wu Jiarong, the managing director of the China-Hong Kong body body factory, the two interviewees, you know!

Behind the body research and development……

Is the all-electric bus the goal?

At present, electric vehicles are popular in many places around the world. Therefore, some people may ask why GMi's oil-electric hybrid coaches are not directly driven by all-electric. Lu Zhipei, managing director of GMi, had this explanation when answering this question. "From beginning to end, we wanted to launch an all-electric bus, not an oil-electric bus. The emergence of fuel-electric buses is only because we have not seen that Hong Kong has a comprehensive charging system for commercial vehicles. There are many for private cars, about 1,500 to 2,000, but for commercial vehicles, there is no one, so it is necessary toIt is basically impossible for the fleet to be driven by all-electric power. Even if a large fleet can set up chargers in the depot, it is impossible to support all its cars. For example, when the car is collected at night, when all the cars have to be charged, one or two chargers alone cannot handle it. 」

Lu Zhipei, Managing Director of GMi

(CP Lo, Managing Director – GMI )

Add battery life

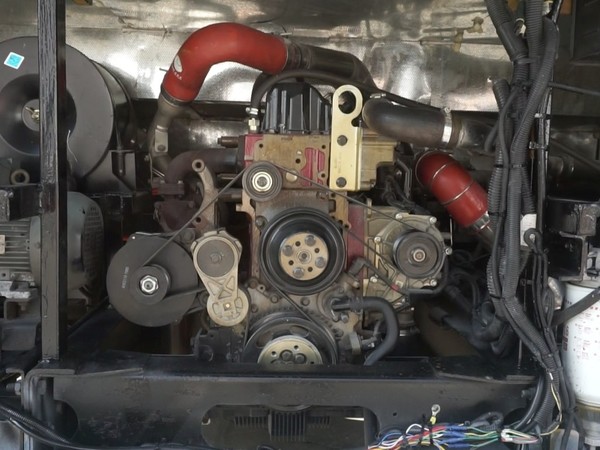

Lu Zhipei also pointed out that GMi's oil-electric hybrid coach is also an all-electric drive vehicle. "It's just that the car is equipped with an On-board generator, which is a generator. When the battery is low, it will automatically charge the battery. In the electric vehicle industry, it is called a battery lifter. Our model is a bit different from the battery life used in ordinary electric vehicles. Generally, electric vehicles will "wait" until the battery returns to the home before charging, while GMi's oil-electric hybrid coach is used to charge the battery during driving, so the whole car can be like ordinary.Like a car, it is driven by electricity after it is oiled. "As for the body, it is equipped with a fast charging function, which can be fully charged in about 30 minutes. When fully charged, it is driven by pure electricity and can walk continuously for 40km.

Superfast Charging OppCharge-enabled Electric Coach GMi oil-electric hybrid coach has a fast charging function, which can be fully charged in about 30 minutes. When fully charged, it is driven by pure electricity and can walk continuously for 40km.

Explanation of the 3 major advantages

Although an all-electric bus is the ultimate goal of Lu Zhipei's research and development, it does not mean that this oil-electric hybrid coach has no advantages at all. Lu Zhipei mentioned that this oil-electric hybrid coach has three major advantages: "One is fuel saving, because the efficiency of pure electric operation is higher than that of pure oil operation; the second is environmental protection, because exhaust emissions can be reduced by 70%; and the third is because it is an electric bus.In the relationship between cars, electric vehicles generally have much less maintenance opportunities. Because there are fewer moving parts, the motor basically does not need to be repaired. At most, the bearing will be replaced after 10 years, so it can be said that there is no maintenance.

Also because the operation of the engine in the car only uses speed, it will only operate at the best stage of the battery, so even if the oil and water are changed, it is far from the traditional car, and it takes a long time to replace it. There is no problem. "In addition, Lu Zhipei also explained other benefits of electric vehicles, such as the reverse charging function. When the car is slow and the slope is falling, because there is power to drive the motor, then the motor seems to have changed at this time. The drag wave occurs when driving, and the electric vehicle battery is charged. At the same time, because the car uses an "electric brake", the traditional brake is not used, and the corresponding time to change the brake leather can be delayed by 4 or 5 times than the average car.

GMI Electric Coach Batteries by Toshiba charging plugs are located on the roof of the car, on the roof of the car, and the 50kWh lithium titanate battery is on the side of the car where the luggage is placed.

The biggest feature of the GMI Range Extended Hybrid Electric Coach body is that it can charge the battery during driving, unlike ordinary electric vehicles that need to "get" the battery and only charge it when they return home.

Front board of GMI Range Extended Hybrid Electric Coach Lu Zhipei mentioned that the most appropriate battery operating power is between 40% and 70%. And he also pointed out that because the battery will not be fully charged, the battery life will be 5 or 6 times longer than the average battery.

Behind the body manufacturing……

One-hand production of oil-electric hybrid bar

GMi's oil-electric hybrid coach, except for the automotive technology, the driving part is independently developed locally, and even the body production is made in Hong Kong. It is managed by the Hong Kong and China body manufacturing factory, and Wu Jiarong, the managing director of the factory, emphasized that "it is not assembly but production." Wu Jiarong mentioned: "GMi's oil-electric hybrid coach, both in terms of shape and body shape, is developed and produced by ourselves, and we only spent about 1 month to make it, because it is very different from the materials and production used in general tourist buses.Similar. The only thing is that the oil-electric hybrid tour bus is not as good as the average tour bus with engine included, so the noise will be less, and the sound insulation part can also be made a little more streamlined. 」

Pay attention to balance and achieve zero noise in driving

Although Wu Jiarong's oil-electric hybrid coach is very similar to the production of ordinary tourist buses, if you want to analyze it in detail, in fact, the former will pay attention to the backbone part to achieve zero noise in driving. "We will focus on the body balance of the oil-electric hybrid coach. Because the traditional bus will have an engine at the rear, the balance between the front and rear of the body is also very important. Now the engine volume of this oil-electric hybrid coach is relatively small. Of course, there are electric-driven cars.In principle, it is to be quiet enough, so we also pay more attention to the sound insulation of the engine room to achieve the effect of zero noise in driving. 」

Made in Hong Kong is definitely a selling point

Finally, one of the questions asked about Wu Jiarong was: "GMi, an oil-electric hybrid tour bus made in Hong Kong, is it one of the selling points?" "He replied: "Absolutely." Although many electric private cars and electric vehicles have been introduced into Hong Kong in the past few years, they are all from the mainland or foreign countries, but they are independently developed and produced by Hong Kong. GMi's oil-electric hybrid coach should be the first one. Therefore, I believe that with this bus, Hong Kong will be a green and environmentally friendly means of transportation.The trend will continue to develop and continue. 」

Wu Jiarong, managing Director of China-Hong Kong Body Body Factory.

Wu Jiarong said that both in terms of appearance and body shape, they were developed and produced by the manufacturer itself, and the production time only took about 1 month.

The sound insulation of the engine room will be an important part of the production of the body, in order to achieve the effect of zero noise in driving.

In terms of luggage and seats in the trunk, it is no different from ordinary tour buses.

More attention will be paid to the balance between the front and rear of the body, because the engine volume of this oil-electric hybrid coach is relatively small.

The cross-section of the body with horizontal, straight and oblique intersections helps buffer the impulse of the body when it is hit and reduces the chance of injury to passengers.